Greetings! In the previous article on cargo cranes, we considered general issues of crane operation and repair for a ship's electrician. The topic of grabs was also touched upon with a link to a separate article.

Therefore, in this article we will "deal" with grabs and their frequent breakdowns. First, let's consider grabs with radio control. These grabs open from a remote control, which is operated by the crane operator or a worker on deck.

This article has been hanging in my drafts for about three years, I just couldn't finish it. I gathered my strength and actually ask you to read it. Especially relevant for beginners!

Radio grabs GBM and TOBU

The main elements of the radio (electro-hydraulic) grab are:

- The radio module (receiver) receives a signal from the remote control (transmitter). Transmits a signal to the solenoid valve coil.

- The remote control (transmitter) is the main control element of the grab. Gives a command to open. The remote control has its own batteries (usually 3A or 2A).

- Battery - a battery that powers the radio module.

- Solenoid valve and coil - affects the main hydraulic valve for opening the grab.

Very convenient grabs for an electrician in terms of maintenance and repair. The most important thing here is to change the batteries in time. Usually, four grabs (batteries) are in operation and, accordingly, 4 batteries are on charge. Batteries can be changed once a day or every few days, depending on the intensity of work, as well as the type and power of the batteries.

Attention! Here we will not consider the grab hydraulic system. I will only describe what kind of breakdowns there are from a mechanical point of view. Also, from the maintenance points I will not talk about lubrication of moving parts, these are self-evident processes of maintaining the grab's survivability.

Chinese Grab GBM

Let's look at Chinese Grab GBM.

A 12 V 38 Ah battery with a display of the battery capacity status is used. By the way, after 4 years of using these batteries, the displays stopped showing the capacity correctly, some batteries lost their capacity and worked for less than a day.

In order for the battery to start working (giving off a charge), you need to connect the radio module to it and press the “Power” button. The same thing needs to be done to put the battery on charge (by connecting the charger to it).

First, you need to press the red button on the remote control, then press the “Start” button and then you can press the “Open” button. Accordingly, the radio module will receive the signal and supply power to the solenoid and the grab will open. The “Keep Open” button allows the operator not to hold the “Open” button to fully open the grab. It is enough to press “Keep Open” once and the grab will gradually open. To disable the function, you need to press “Keep Open” again.

The problem with this button is that if the crane operator leaves the grab in the cargo hold with the “Keep Open” button pressed and goes for a smoke break, the radio module and solenoid will gradually discharge the battery (the solenoid will be constantly supplied with power). Therefore, if possible, it is better to “mute” this button.

If it is impossible to open the grab with the radio module, it can be opened using the emergency button on the solenoid. Unfortunately, this model of the grab has a button, but there is no remote pressing of this button. For example, in Japanese TOBU grabs there is a special lever to which you can tie a rope, lower the grab with the load into the cargo hold, pull the rope and the grab will open.

The main problems with GBM grabs over the long years of operation were with the hydraulic system. Small particles of dirt got under the main valve and the grab stopped closing. There were also problems with the safety valve, due to which the grab opened slowly. In the first case, disassembling and grinding the valves helped, in the second - adjusting the safety valves. After changing the oils, such problems no longer occurred.

Video of the main valve in operation

As for the electrical part, there were problems only with the batteries, they could not hold for a day. Replacing the batteries with newer ones solved this problem.

Video of the GBM grab solenoid in operation

Video of the GBM grab in operation

Japanese grab TOBU

Let's consider the Japanese grab TOBU.

These grabs usually use nickel-cadmium batteries. Of course, newer vessels may already use lithium-ion or gel batteries, which significantly increases the battery replacement period during cargo operations.

The control distance of the grab (from the remote control to the radio module) is approximately 50 meters. By the way, it is very important that there are no signal barriers between the module antenna and the remote control. Otherwise, the grab will not open when a signal is sent.

Radio module LED indication helps to determine the module's serviceability if troubleshooting is required.

If the batteries in the remote control are discharged, the red light will be on. By the way, this remote control uses AAA batteries, but the GBM radio module uses AA. You can use rechargeable batteries. Usually, for cargo operations of 50 - 60 thousand tons of cargo, it was necessary to change the batteries in the remote control once.

AIR BREATHER (INHARANT VALVE). This valve intakes the air. To use grab, attach this valve on oil tank plug. While not using grab, detach it from tank.

The air vent on the oil tank is a very important element of the grab. It must be installed before cargo operations, and its condition must be monitored. If the air vent does not work, then there may be problems with the grab, it will stop closing or opening (or perform these operations very slowly).

The main problems with TOBU grabs, as well as with GBM, were related to the hydraulic system and moving parts. Problems with air vents can be added here. In the electrical part, I once had an experience of the radio module failing, once the antenna was broken, and so nothing critical.

I also had the chance to work with Chinese Noname radio grabs, which were apparently assembled from different parts of other grabs.

Such batteries (lead-acid batteries) are very heavy, so you have to take partners to replace them. But they can last for the entire process of cargo operations without charging (replacing).

The photo above shows the grab emergency opening system (a special lever to which a rope is tied).

The grab does not open. What to do?

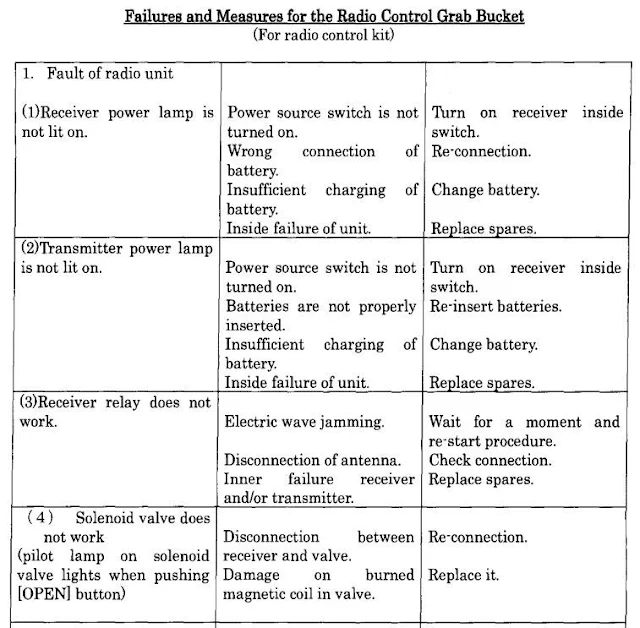

If the grab does not open, then from the point of view of the electrical part, everything is simple. It is necessary to check the chain remote control - radio module - solenoid valve, check the main battery, batteries in the remote control, and the solenoid itself.

If power is supplied to the solenoid valve, and the coil is intact (it is necessary to measure the resistance of the coil), then there are no problems in the electrical part. This means that you need to look at the hydraulic system and the mechanical part.

Thus, troubleshooting such grabs for ETOs is very simple. Another thing is with grabs with electric drives and cable control, as well as with a turbo coupling system.

Electric-driven grabs (with cable control) SMAG PEINER Greifer MZGL

Let's consider the German grab SMAG. Unlike the previous grabs, it has an electric drive for the hydraulic pump. And accordingly, if there is an electric motor, then it has an electric control and protection circuit.

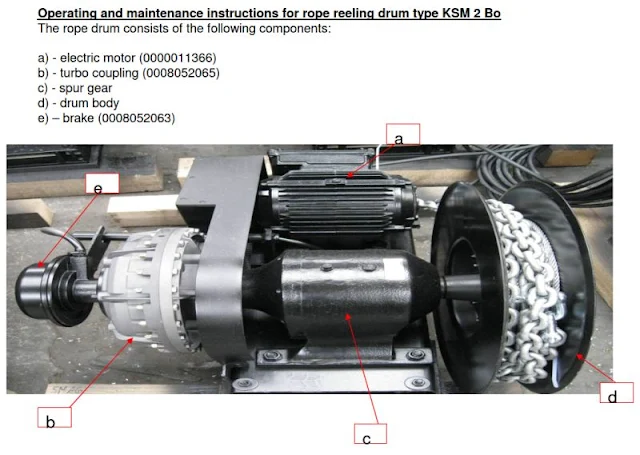

The grab electrical circuit consists of three electric motor circuits. One electric motor is the motor inside the grab, which is responsible for opening and closing the grab. The other two motors are the turbo coupling electric drives. One is the motor power cable in the grab, the other is the grab stabilization cable. Turbo couplings will be described below.

A cable drum is a drum with a power cable for controlling an electric motor. The cable has a special power plug for connecting to the motor socket on the grab. It is connected to the grab simply in a power socket, like, for example, a reefer container on the deck or a high-pressure machine (for cleaning the deck from rust). During operation, the power cable is automatically unwound (the grab is lowered) or wound (the grab is raised) on the drum. This is all implemented using turbo couplings.

A cable drum (stabilizer) is a drum with a cable that is attached to the grab to stabilize it. Since we have a power cable connected to the motor, which essentially hangs in the air (unwinds and winds up due to turbo coupling), a stabilizer is also needed that will hold the grab in one position so that it does not twist, otherwise the grab cables will twist with the power cable, which is unacceptable. The stabilizer, like the cable drum, automatically unwinds and winds up due to turbo coupling. The cable and cable are always under tension, depending on the position of the grab.

The power cable plug consists of many components, mainly for the implementation of reinforced insulation of current-carrying parts. After all, the grab has an electric motor with a power of 33 - 44 kW, voltage of 440 V. By the way, pay attention to the rubber cover, it is used to insulate the plug when the grab is not in use. It is very important to ensure that this cover is sealed and does not let water through.

The power cable on the grab should have a slight sag, it cannot be completely under tension from the socket to the drum, this is unsafe, therefore a special cable pulling mesh (snake grid) has been implemented, which, due to chains of different lengths, creates a slight sag in the cable.

The crane should have a special place for fastening the power plug when the grab is not in use. It is important to ensure that the rubber cover (described above) tightly closes the plug. You can use, for example, vaseline for additional protection of the cover gasket from moisture getting inside.

A brush apparatus is used in a cable drum - a very important link in the power section of the grab electric motor. It is necessary to periodically check the condition of the brushes, all moving parts, as well as the tightness of this unit.

The cable drum and the cable drum (stabilizer) in the drive system (reduction gear - turbo coupling) use belts (two belts on each drive).

It is very important to constantly monitor the condition of the belts, as they are located on the open deck and operate in an aggressive marine environment.

Cable and cable sheaves are guide rollers on which the cable "rides". It is very important that they are in good condition and do not jam, otherwise there may be problems with cable tension and grab stabilization.

Turbo coupling is a hydrodynamic coupling, which is a device for smooth and shock-free connection of the engine and the working mechanism. It consists of two main components: a pump wheel and a turbine wheel, which rotate in a housing filled with a working fluid (usually oil). The principle of operation is based on the transfer of torque from the engine to the mechanism due to the movement of the fluid.

Main elements of turbo coupling:

- Pump wheel: Connected to the engine and accelerates the working fluid.

- Turbine wheel: Connected to the driven mechanism and transfers the energy of the fluid to it.

- Housing: A closed space where the working fluid is located.

How turbo coupling works:

- The engine (motor) rotates the pump wheel, which makes the fluid move.

- The flow of fluid enters the turbine wheel, transferring energy to it and rotating it.

- The turbine wheel sets the working mechanism in motion.

Advantages of turbo coupling:

- Smooth start and stop.

- Reduced shock loads when the mechanism is turned on.

- Possibility of adjusting the shaft rotation speed.

There is one very important point in servicing turbocouplings - the oil level. If the oil level in it is insufficient, there may be problems with the cable tension or stabilization of the entire grab. For example, the power cable may have a significant sag and this will lead to its twisting around the grab cables. As a result, it can break. The same thing can happen if there is not enough oil in the stabilizer turbocoupling, the grab will start twisting and, accordingly, break the cable. A cable break is a very serious problem, the solution of which can take a whole day. By the way, the vessel should have at least one new power cable in stock.

Here I will not describe the procedure for checking the oil level in the turbocoupling (no measuring glass is provided) and how to add it, focusing on the current and operating temperature of the turbocoupling. All this is described in the instructions. Just keep in mind that before each cargo operation it is necessary to check the operation of turbocouplings, namely how they stretch the cable and rope (for at least an hour of operation). If the readings are bad (tension level and currents), then add oil according to the instructions.

If you are interested in my experience of checking and adding oil to turbocouplings of these grabs, then write in the comments to this article and I will add a short instruction from my experience.

A very important component for the electrician of both turbo couplings is the electric brakes, which are used in the motor drives. If the brakes do not work correctly, this will also lead to incorrect operation of the stabilization system.

Electrical components of the grab control circuit

Motor circuit breakers Q1, Q2, Q3 act here as protection for electric motors from current overload.

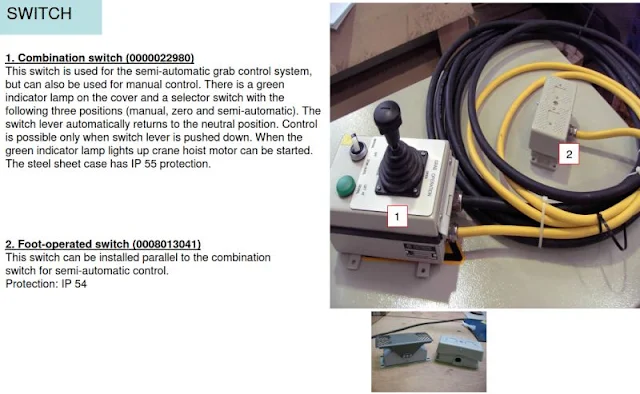

Timers protect the control circuit and electric motors from incorrect operator actions.

The grab can be controlled either with the manipulator (switch in the "Manual" position) or with the special Pedal Switch pedal, switch position - "Semi-Auto"). There are separate handles for the cable and rope drum. The "PULL" mode is always used, both in grab operation and in the tension test mode. The "LOWER" mode is used for maintenance. Neutral position - to turn off the turbocoupling electric drives.

Troubleshooting SMAG grab

Troubleshooting SMAG grab is actually very large, because... This system uses many components, both electrical and mechanical (hydraulic). Below I have posted only the main troubleshooting, the most common problems.

Checking the insulation resistance of cables and electric motors

Checking the insulation resistance of cables and electric motors is probably the most important job of an electrician when servicing deck mechanisms. And these grabs are no exception. The photo above shows the process of detecting low insulation (0 MOhm) of the power cable, it turned out that the internal contacts of the plug were corroded. Apparently, the rubber cover, which was written about above, let moisture through and natural corrosion of the internal components of the plug occurred. The insides of the plug were replaced, the insulation was restored. The same thing can happen with sockets on grabs. The photo above shows that the insulation of the motor and the contact group of the socket is more than 150 MOhm.

Cleaning the power contacts of the two contactors of the grab's electric motor is another key moment in preparing the grabs for work. Before each loading operation, it is advisable to clean all the contacts. Due to the intensive use of the grabs, these contacts can burn badly, and accordingly, uneven contact leads to an increase in current and the main circuit breaker tripping, and the grab stops working.

By the way, I forgot to say that our motor is reversible and the reverse is implemented due to two power contactors.

The electric motor is reversed by switching the phases in the windings, which changes the direction of rotation of the rotor.

The basic principle is to swap any two of the three phases, which will change the direction of the rotating magnetic field, causing the reversal. There are several ways to switch the phases:

1. Manual control

A reversing switch or toggle switch is used, which manually switches two of the three phases.

2. Reversing starter

Two magnetic coils with contacts are included in the circuit: one is responsible for forward rotation, the other for reverse.

When one coil is turned on, the motor rotates in one direction. When the second coil is turned on, the phases change, and the direction of rotation becomes reversed.

3. Programmable logic controller (PLC)

The controller controls the reversing starter, automatically switching the phases when necessary.

A PLC is usually used in more complex and automated systems to control the reversal of the motor according to a given program or operator commands.

For safety reasons, reversing circuits always use interlocks to prevent both coils (or the reversing contactor) from being turned on simultaneously.

Checking the oil in the turbo couplings and the tension of the cable and rope

Video of checking the operation of turbo couplings

Video of checking the operation of turbo couplings

Video of SMAG grabs in operation

Video of SMAG grabs in operation

The grab does not open or close. What to do?

If the SMAG grab does not open or close, then you need to act in the same way as when checking the operation diagram of any other electric drive. That is, we take the electrical diagram and first of all check all the protections. Have the circuit breakers tripped, have the fuses burned out, how do the timers work. We check the operation of all moving grab control systems, manipulators, switches, pedals. We check the insulation resistance of the cables and motors.

By the way, if you still don't know how to read electric drive circuit diagrams, I recommend the article "How to read electrical diagrams on a ship? Main engine turning gear operation diagram". Using it as an example, you can also easily read the circuit diagram of an electro-hydraulic grab with cable control.

From practice, I will add about the problems that happened to me or on the vessels I worked on, but not with my participation:

- A cable breakage due to improper operation of turbo couplings (insufficient oil). The crane operator did not notice a significant sag in the power cable and cut the cable with a grab.

- The main motor circuit breaker tripped due to heavily charred contacts of one of the contactors.

- The grab electric motor burned out. The reason is low insulation.

- Low insulation of power plugs and sockets. As a result, the circuit breakers were tripped.

- Failure of the control circuit timers.

- Failure of the operator pedal.

- The belt on the turbo coupling electric drive broke during cargo operations.

These grabs are quite reliable, but constant maintenance is required, i.e. regularly monitor the insulation, belts, brushes, oil, and also combat the aggressive marine environment (remove rust, renew the protective paint of the outer parts).

If you have any questions or have something to add from your experience, then write in the comments to the article.

Manuals and videos. By the way, all manuals for these and other grabs are available in our closed telegram channel Marine Engineering Manuals. And if you want more videos on the operation of cargo cranes with grabs, then subscribe to the YouTube channel ETO ENGINEER.

I hope this article was useful for you! Thank you for your attention!

-min.JPG)

-min.JPG)

-min.JPG)

-min.JPG)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

-min.jpg)

.jpg)

No comments:

Post a Comment